Perfect business synergy

Dave Thomas, managing director at Haffner, discusses the benefit the exclusive partnership with Graf Synergy will deliver for fabricators.

It’s fair to say that the industry has changed: demand for windows, doors and conservatories has never been higher, with more fabricators recording record sales than at any other time.

On the face of it, this boom in sales is good news for the industry, but it has identified a pinch point on most fabricators’ businesses, especially when it comes to production output. As a result, more fabricators have turned to machine automation to scale up quickly and easily giving them the means to react to demand.

The increased demand for automation machinery is something we had witnessed well before the pandemic hit, as the ability to produce more with less was always a compelling proposition for most shrewd fabricators. But since the reopening of the industry after the first lockdown, the demand for machine automation has grown exponentially.

Creating a factory that runs on automation cannot be done without extensive process control and having the right machines in place to not only allow production scalability but ensure a high-quality finish. And, as a business, we have continually aligned our machinery offer to reflect what fabricators need, regardless of manufacturing size or output.

We already have a growing order book for our range of Haffner and Fom Industries machines that deliver extraordinary manufacturing efficiencies at every level. And by completing our exclusive partnership with Graf Synergy, our machine offering is now the largest and most comprehensive in the industry.

Having been in discussion for some time with Graf Synergy it was clear that Graf was not getting the exposure it deserved for its range of machinery in the UK. As such, Gianfranco Ferranti and I signed an exclusivity agreement that meant Haffner is the sole distributor of Graf Synergy machinery in the UK and is committed to further consolidating Graf Synergy’s presence in the UK fenestration market.

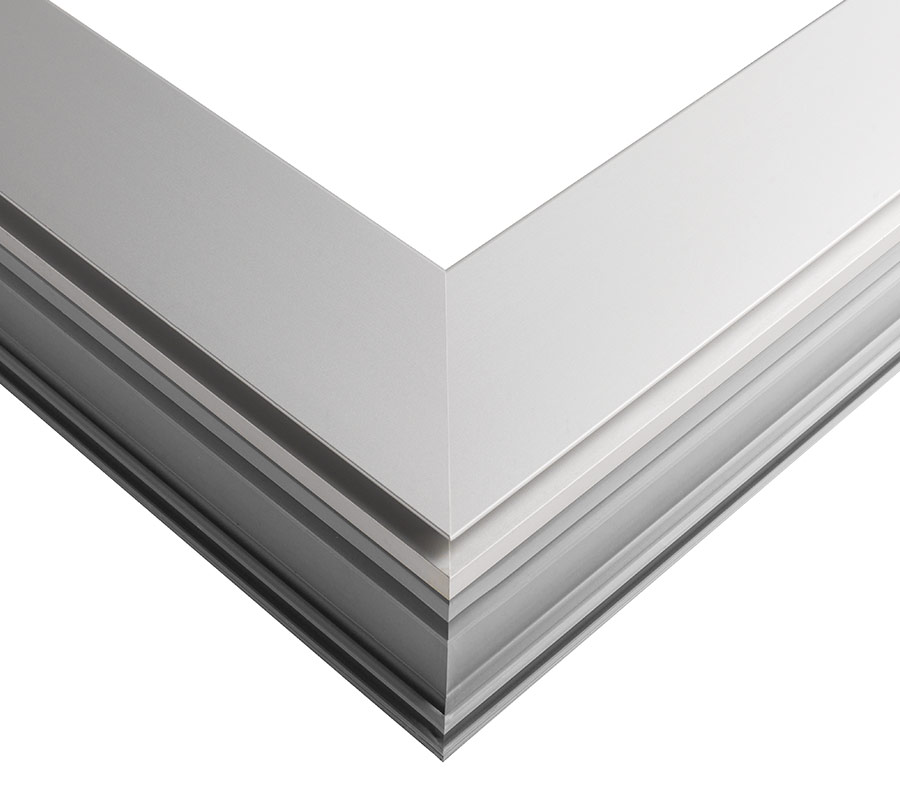

The range of machines available from Graf Synergy is exceptional and offers state-of-the-art automation at every level for both aluminium and PVCU fabrication. It is probably best known for its world-class seamless welding technology and patented welding techniques that deliver superior product quality. And with the increasing demand from the domestic sector for feature-rich products, having seamless welding technology in your manufacturing is crucial to deliver on the high-end cosmetic detailing consumers now demand.

Graf Synergy’s range offers solutions for fabricators of all sizes. The machines are ideal for the manufacture of ‘heritage’ high-end products such as flush casements or sash windows but equally appropriate for high volume casement output delivering high levels of automation throughout the entire process.

To support customer demand, we recently increased our highly trained UK engineers to 10, and have made several new appointments at our Staffordshire headquarters.

Having recently commissioned several large-scale investments including a new 1,900m2 showroom extension at our Stafford headquarters, and committing to a record 405m2 stand at FIT 2021, we are optimistic about achieving our continued growth strategy for the business.

The new exclusive collaboration with Graf Synergy blends the innovative expertise of the two businesses perfectly as we continue to deliver the best in fabrication machinery for our customers.