Automation beyond efficiency

Tony Palmer, head of sales at Edgetech, explores how automation can create new career paths in IGU manufacturing and make a big dent in the skills shortage.

We often discuss automation purely in terms of production metrics, such as speed, accuracy, and output. Of course, these are vital considerations, particularly in today’s challenging economic environment for the glass and glazing industry.

I believe, however, there is another story worth telling – how automation is reshaping the workforce itself.

At Edgetech, we’ve worked with IGU manufacturers across the UK and beyond for decades, and in recent years, the pressures on our sector have been immense, with expectations on quality and consistency intensifying and recruitment becoming extremely difficult.

In response, many businesses have understandably looked toward automation to keep production running efficiently.

But what we’ve observed time and again is that the most transformative impact of automation isn’t always measured on the production line – it’s seen in the people who run it.

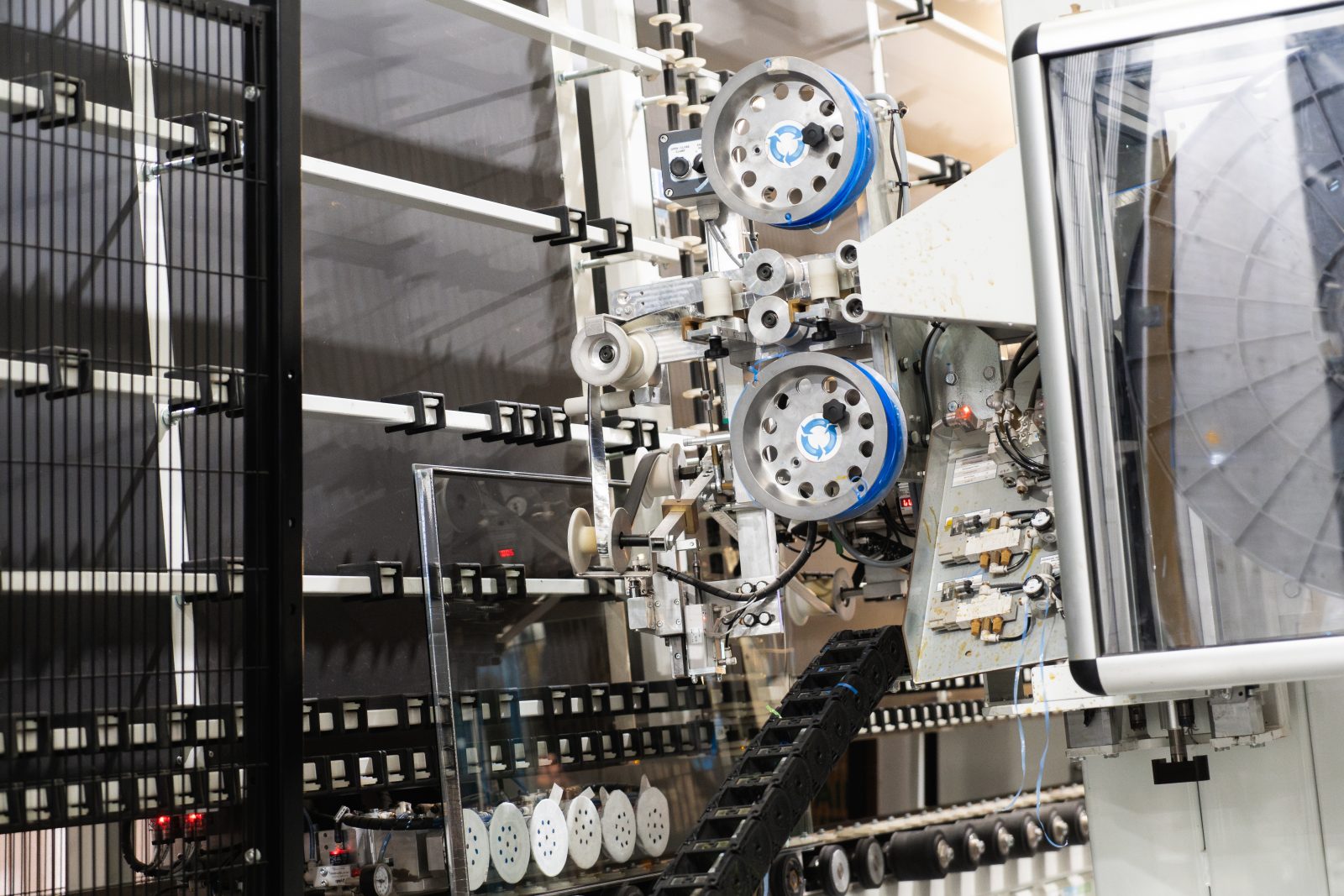

Traditional methods of applying spacer bars – whether fully manually or what we term ‘semi-automatically’ – are repetitive, physically demanding, and often limit an individual’s opportunity to grow. With automation, that changes entirely.

Rewarding roles

Suddenly, a role that once involved manually applying spacers becomes a stepping stone to operating advanced machinery, interpreting data, or leading quality assurance efforts. Staff who might have had little exposure to technology in the past are being trained to monitor performance metrics, conduct diagnostics, and even optimise processes.

They’re learning transferable skills that align with modern manufacturing and open the door to long-term career progression.

For employers, this shift brings significant advantages. By giving employees, the chance to develop new skills, they’re investing in a more engaged, motivated, and loyal workforce. In an industry grappling with retention challenges and a shortage of young entrants, that’s a huge benefit. Automation isn’t about replacing people.

A talent magnet

Historically, manufacturing has struggled to attract fresh talent and unfortunately, in Britain we have an ageing population, which means that thousands of the most experienced manufacturing professionals are set to retire over the next 15 years.

Automation can attract a new generation of younger, tech-savvy talent to our industry. These individuals are drawn to roles that involve innovation and technology, and view automation as an opportunity rather than a threat.

This changing perception is key to the future health of our sector and by modernising not just our machinery but our message, and by showing that a job in fenestration can mean working with automation technology, we make glass and glazing far more appealing to the next generation.

A cultural shift

Naturally, automation still brings substantial production benefits, such as increased output with fewer than half the operators required for manual production. But the human return is just as powerful, with more output and less burnout.

Teams are no longer stretched thin, managing relentless production quotas under tight deadlines. Instead, they’re deployed where they add the most value, allowing businesses to unlock the full potential of their staff.

As more businesses explore automation, we encourage them to think beyond the immediate operational benefits.

At Edgetech, our mission has always been to support IGU manufacturers not just with innovative spacer technology, but with insight, guidance, and long-term partnership.

The conversation around automation is no longer just about machines and how we make IGUs. It’s about people and how they can thrive in a new era of manufacturing.