Could machinery investment solve your recruitment crisis?

By Ian Latimer, managing director, Emmegi (UK).

A customer told me a story just before Christmas about recruiting two new young operators to work on the factory floor. One didn’t turn up at all, and the other walked out mid-morning on the first day after he was reprimanded for being 40 minutes late (although his Mum did phone later asking for him to be given a second chance!)

This might be an extreme example, but it does show the challenges which some employers in this industry continue to face when it comes to recruitment – despite the fact that unemployment rates have just topped 5% and rates for 16 to 24 year olds are closer to 16%.

We’ve talked for a long time in this industry about the struggle to recruit skilled workers, but in many areas of both the UK and Ireland, where Emmegi also has a strong presence, recruiting unskilled workers is almost as difficult.

There is a raft of societal and economic reasons for that of course – which probably go back even to before Brexit, and which successive governments have tried (and largely failed) to tackle; but the struggle for employers persists.

If you add to that the rising costs of employment, it’s little wonder that manufacturers are increasingly looking for ways to recruit less and optimise the efficiency of their existing workforce, while still being able to grow their businesses.

Annual wage growth in the UK is currently 4.7%, on top of the increased employer NI costs and above inflation rises in both the minimum and living wage which are due in April. Taken alongside the recruitment crisis, it makes a compelling argument in favour of increasing investment in machinery.

It’s obvious that the right choice of machinery can transform the efficiency of any factory, automating complex processes, delivering quantifiable return on investment and, crucially, reducing dependency on labour.

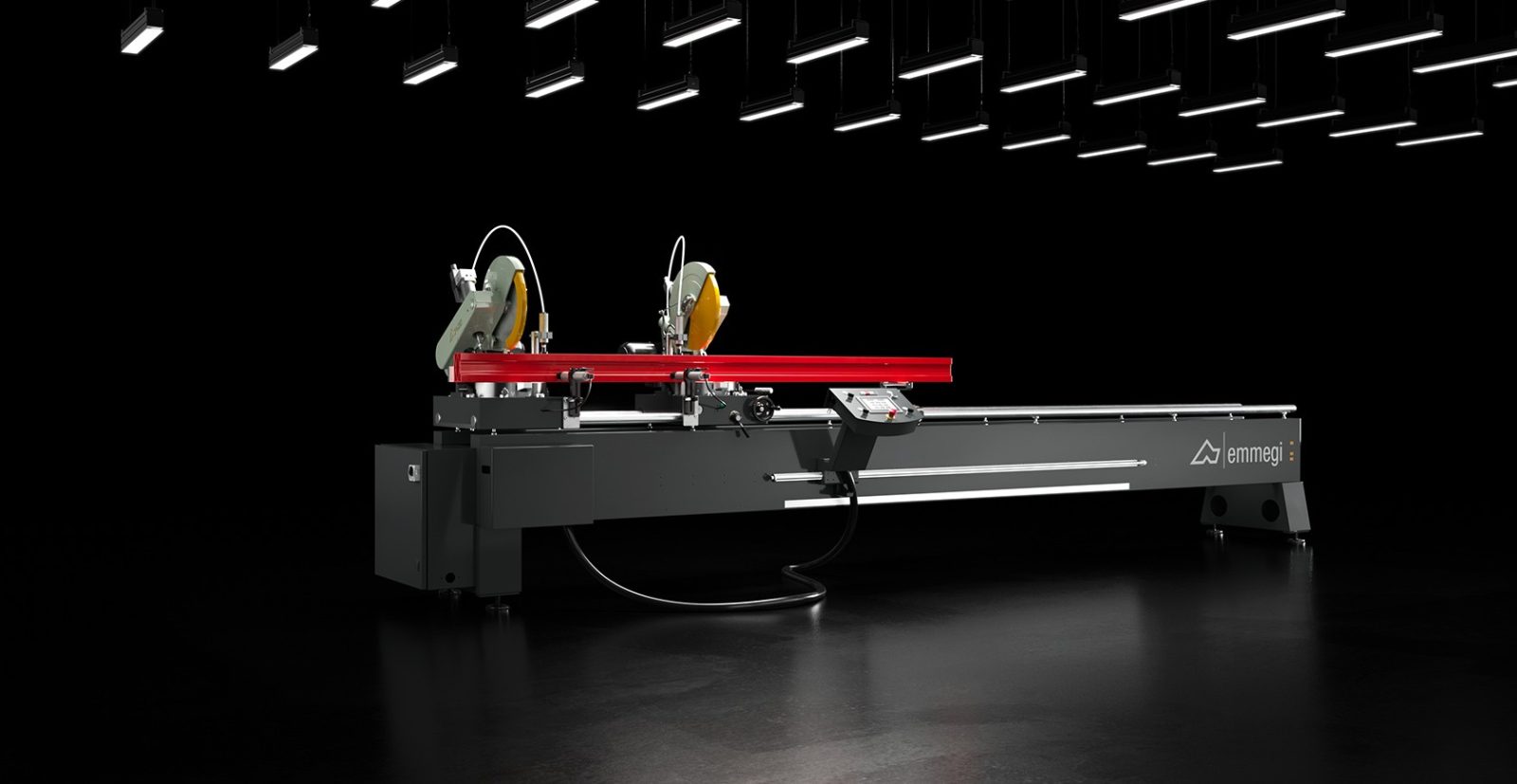

Even Emmegi’s entry level machines like the Phantomatic M3 CNC, Norma E twin head saw and Nanomatic 384S copy router will make a dramatic impact on the volumes and efficiencies of any factory – with fewer operators required per shift.

Take a step up to a four or five axis CNC like one of Emmegi’s Satellite or Comet models, and the efficiencies multiply in line with the investment. The Emmegi Satellite XT, for example, which can cut and prep curtain walling profiles, features a mobile gantry which allows different workpieces to be machined at the same time in two separate work areas, or one end loaded and unloaded while the machine is operating at the other end.

Similarly, the Comet R6I can operate in single or double zone modes for machining either a single bar length up to 6m or multiple shorter lengths at the same time. The I in the model classification means the machine offers ‘Independent’ positioning of the servo-controlled vices, so that, when the electrospindle is operating, the machine can be automatically setting up the vices ready for machining in the next area. This obviously has the potential to save significant amounts of operator time.

And, for probably the ultimate in efficiency, Emmegi proudly boasts that our flagship 20-axis Quadra range can effectively do the work of a team of fabricators. These machines cut, drill and machine in one, which also mitigates the tolerances which are normally incurred at each separate stage, and deliver unrivalled levels of precision and accuracy on even the largest scale volumes.

In terms of payback on machine investment – estimates vary widely depending on the machine and the previous set up. But it can be as little as 12-24 months if you take into account savings on labour, optimised material usage, shorter cycle times and higher outputs. With a vast range of machines in our range, the Emmegi (UK) team can advise on the right options for any size of business – enabling manufacturers to grow profitably even amidst current workforce constraints.