Automation key to Twinseal’s success

Automation and a partnership with Edgetech that has delivered lasting value has been the catalyst for success for Twinseal.

In 2025, Twinseal is marking a series of major milestones. Celebrating its 50th year in business, 40 years of IGU manufacturing, and 25 years of producing its own toughened glass, the company is also marking another crucial anniversary – 20 years of partnership with Edgetech.

What began as a bold step into the world of automation has evolved into a trusted collaboration that continues to shape Twinseal’s success. And at the heart of this long-standing partnership is a shared commitment to quality, consistency, and innovation.

“We’ve always been early adopters of high-performance materials and machinery,” explained managing director Billy Cowen, who took over the reins from his father Allan, the company’s founder.

“It’s 25 years since we installed our first toughening plant which made us one of the first independent companies in the UK to do so. Then only a few years later, we began using soft coat low e glass from Saint-Gobain.”

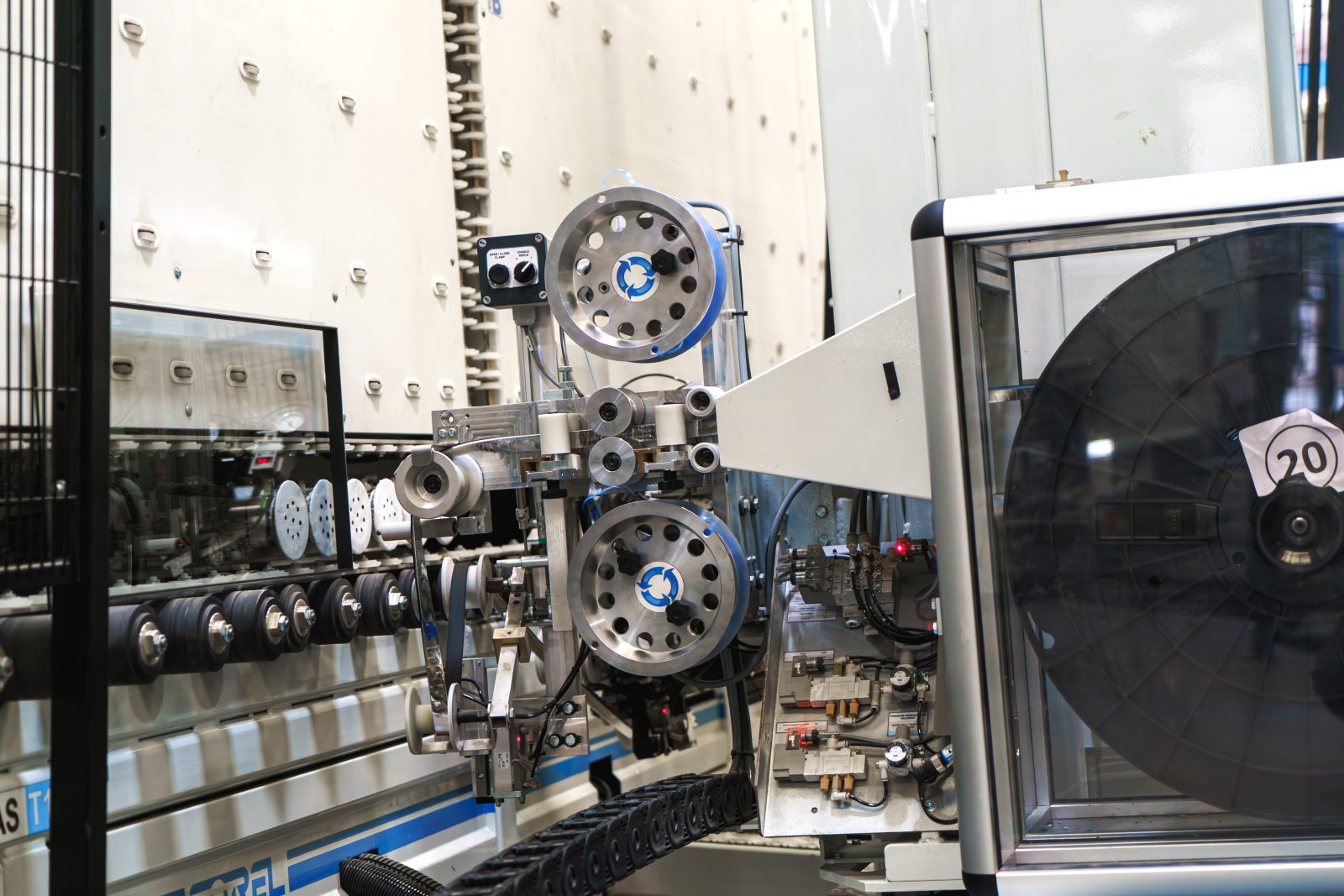

According to Billy, the IGU manufacturer’s investment in automated unit production using Edgetech’s Super Spacer 20 years ago was a game-changer, one that transformed Twinseal’s capabilities and took the business to another level.

Automation adoption

Working closely with Edgetech, and machinery partner Forel, Twinseal’s decision to turn to automation came at a time when few independent IGU manufacturers were taking such a leap, and it’s a move that has paid dividends.

“The driving force behind going down the automation route was always about improving quality and consistency, but also about achieving volume,” explained Lee Cowen, Billy’s son and now operations director at Twinseal.

“20 years later, we’ve surpassed all our expectations. We’re able to produce high-quality units in consistent volumes efficiently, day in, day out. The process is so reliable that we don’t even have to think about it.”

Both Billy and Lee are quick to credit Edgetech’s long-standing support as integral to Twinseal’s journey. “Edgetech has been invaluable and a fantastic partner from day one,” said Billy. “They helped us get up and running, provided guidance on certifications and production processes, and have supported us every step of the way as we’ve grown and evolved. They’re always on the end of the phone to help out if needed.

Lee agrees: “The quality and reliability of Edgetech’s products are impeccable; the product turns up on time, it goes through the machine without any issue, and it helps us get products out the door efficiently. In 20 years of using Super Spacer, I honestly can’t remember a major issue. That kind of reliability and consistency is invaluable in this industry.”

Tony Palmer, head of sales at Edgetech, echoes the sentiment: “Twinseal is a fantastic example of what happens when a forward-thinking manufacturer embraces automation. The company’s commitment to quality and long-term strategic partnerships has helped position it as a leader in the market.

“Over the last 20 years, we’ve worked closely with the Billy and Lee to support their move to automation and beyond. What sets Twinseal apart is their belief in building lasting relationships, both with their suppliers and customers. It’s a model that works.”

Twinseal are now positioned to push the business forward using automation and, with recent investment in a further IGU line for Super Spacer, see the relationship with Edgetech continuing for many years to come.

“We’ve heavily invested in automation again in the past few years, which is not just a commitment to our future, but a commitment to Edgetech too,” added Lee. “They’re a key part of where we’re going as a business. Their product quality, technical support and insight into the market make them an invaluable supplier.”

And Billy has one piece of advice for other glass unit manufacturers considering a similar move: “If you’re thinking about automation, do it. We’ve never looked back and switching to Super Spacer was one of the best decisions Twinseal ever made. Quality efficiency, consistency and the ability to scale are key ingredients to any successful business. Automation helps to achieve all of them.”