How turbo welding can increase your output by 14%

Stuga Machinery is bringing the new Stürtz HSM 6-KV Turbo corner/transom welder to the UK. Ed Williams, managing director at Stuga Machinery explains how it could add more than 163 frames per week to your production line.

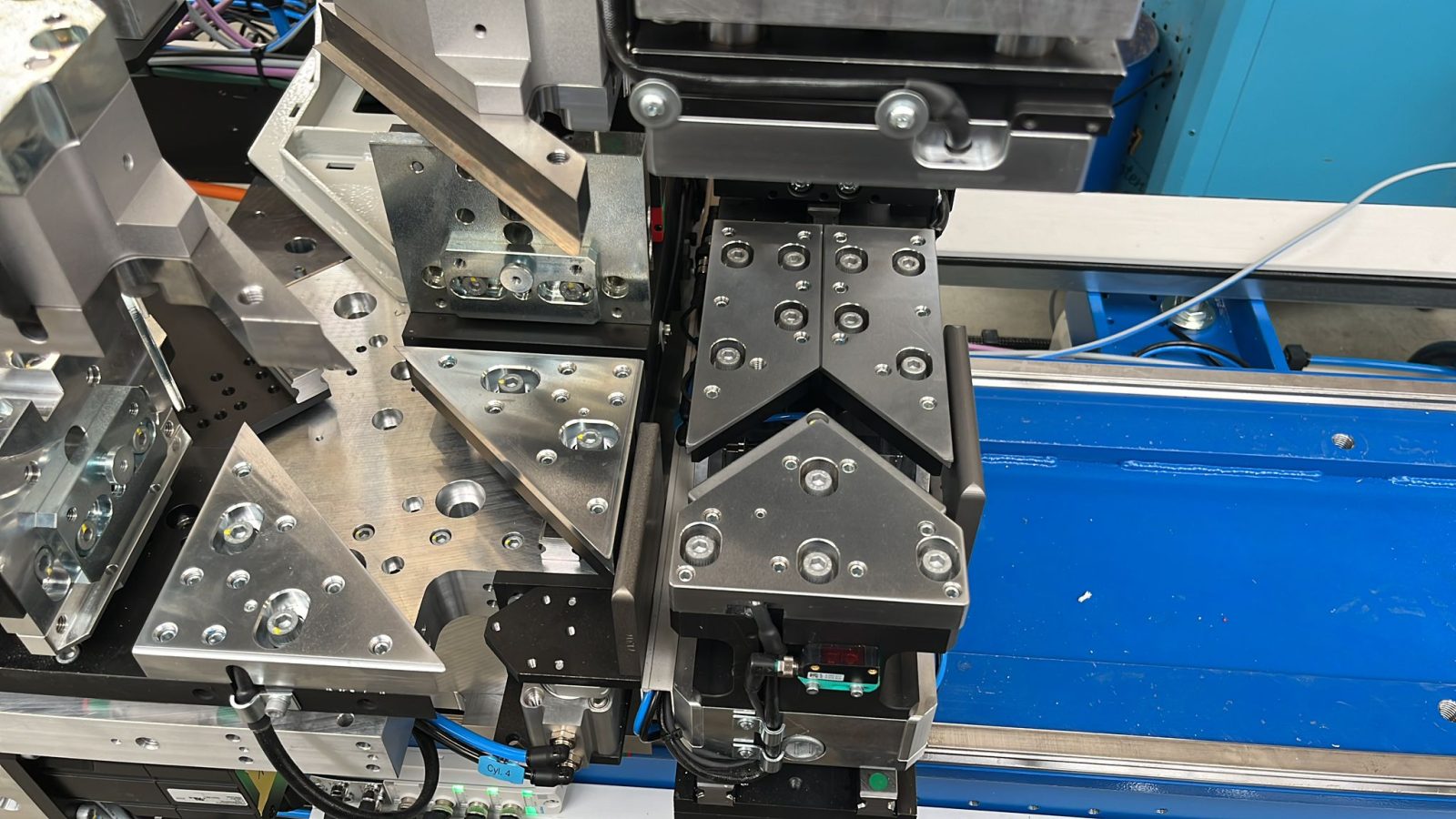

As the exclusive UK supplier of Stürtz machines, we are planning to unveil the new Stürtz HSM 6-KV Turbo corner/transom welder at next year’s FIT Show.

With several orders already received, the first machine is already installed and is transforming production lines with a predicted 14% increase in productivity, or an additional 163 frames per week at 100% OEE.

The new Stürtz HSM 6-KV Turbo brings servo-driven, high-speed welding technology to the UK market, offering manufacturers precise control and significantly higher output, alongside the flexibility to weld a full range of product components: window frames, sashes and doors using this proven Turbo Welding Technology.

Why turbo welding?

Traditional pneumatic-controlled welders rely on air cylinders for the linear movement, limiting control to speed and pressure. The Stürtz HSM 6-KV Turbo, however, replaces these pneumatic systems with servo-controlled axes, providing operators with complete control over each welding phase.

By combining higher heater plate temperatures with gradual, pulsed fusion of the servo axis, Stürtz’s Stürtz HSM 6-KV Turbo produces faster, consistent and durable welds.

It also heats to 280°C and completes fusion in just 10-15 seconds – versus the conventional 240°C and 25-30 seconds of traditional pneumatic welders, with additional time savings during the pulsed fusion phase.

This improved cycle reduces overall welding duration by 15-20 seconds, enhancing production rates by a predicted 14% and upping output by 163 frames per week (based on an eight-hour working day, five days per week), without compromising joint strength.

The Stürtz HSM 6-KV Turbo features a user-friendly operator interface that simplifies the loading and welding sequence. Operators start the sequence, and the machine moves to the optimal loading position, allowing easy placement of the top frame, transom, sides, and bottom frame.

Once loaded, the operator initiates the welding cycle, and the machine discharges the frame onto the corner cleaner line, ready for the next stage.

Enhanced precision and control: Servo-driven rear fences on all corners and transoms provide complete control during fusion and welding phases. Unlike conventional pneumatic systems with basic ‘on-off’ limitations, the servo-driven system allows for gradual torque adjustments, resulting in consistent and durable welds.

Reduced transom drop: The transom head design has been slimmed down, allowing for a smaller transom drop (reduced from 350mm to 230mm). This feature enables the production of smaller frame sizes, ideal for specific window configurations.

Improved efficiency: The turbo welding process shortens cycle times by 15-20 seconds per frame compared to traditional pneumatic-controlled welders. Over a week, this saving of time translates to a significantly higher output, of up to 14%, making the HSM 6-KV Turbo Corner/Transom Welder an ideal choice for high-volume manufacturers.

Streamlined loading process: The HSM 6-KV Turbo offers a loading sequence designed for efficiency. Rear corner heads move closer to the operator during the loading phase, which means easier and more accessible frame loading.

High-speed welding

The Turbo welder combines higher heater plate temperatures and servo-controlled introductions of profiles, resulting in strong, high-quality joints suitable for high-stress applications, and full control via the central control system.

We can’t wait to see the reaction this innovative machine will get at the 2025 FIT Show as we truly believe it outperforms all competition.

We are always striving to not only meet but exceed industry standards, and this machine gives manufacturers a valuable tool for increasing output, optimising production workflows and, ultimately, profitability

Our customers also have a highly comprehensive team ready to assist them. All machines in the Stuga and Stürtz range are supported from our UK manufacturing operation, which provides breakdown, software, planned maintenance, programming and parts capability via a team of 14 field service engineers, two helpdesk technicians, project management and a team of four planning and administration roles.