Ventilation hardware takes priority

By Dean Bradley Glazpart sales director.

When it comes to thinking about hardware, leading window and door fabricators are putting trickle vents on their priority list due to several key factors.

These include ensuring that windows or doors comply with Building Regulations Approved Document F (means of ventilation) but also that homeowner expectations are met with regard to trickle vent aesthetics.

In 2025, we expanded our award-winning trickle vent range with the launch of two new trickle vents for two different and growing niche sectors, the aluminium bi-fold door and the heritage markets.

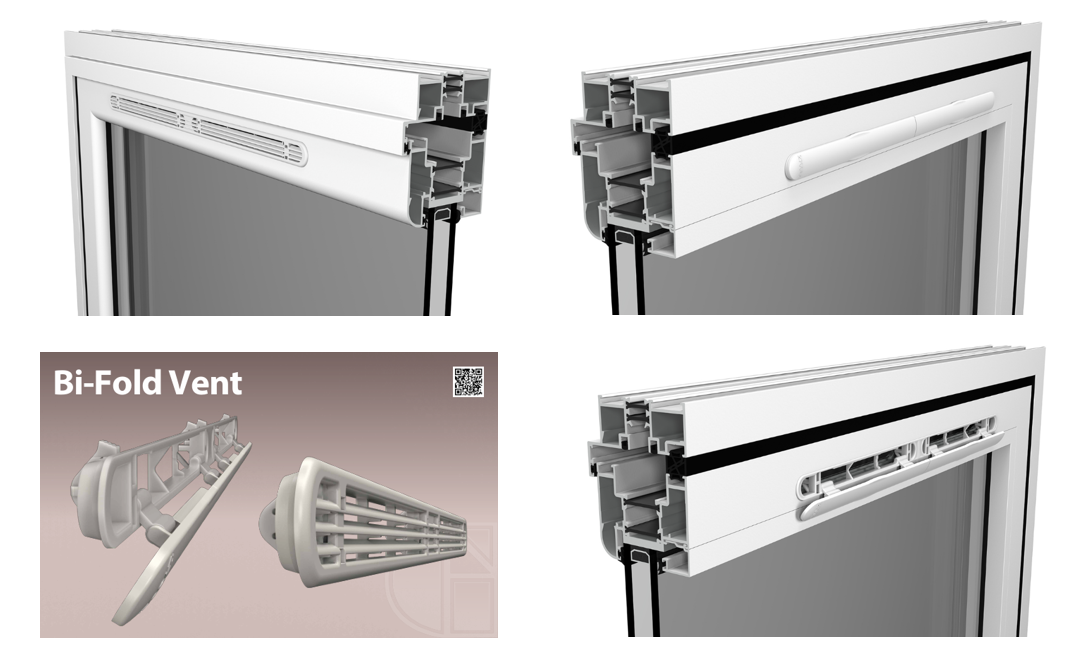

For aluminium bi-fold doors, we manufactured the Bi-Fold Vent – a shallow height (slim) vent designed to work within the low hinge stack heights when the doors in a bi-fold system are in the open position. It has a unique, low-profile louvred canopy design combined with a low profile vent to allow both the internal vent and louvered grille clip to sit easily between the open, concertinaed door leaves.

Designed for compliance with Building Regulations with the independently tested equivalent area (EQA), the Bi-Fold Vent sits in a 16mm rout and in many cases, can be located directly into the door leaf or frame, removing the need for expensive additional ‘knock on’ or extended profiles.

With a 2700 EQA per vent, a three-panel door meets the background ventilation regulations for the room. The tried and tested clip design sits perfectly in the low-profile chassis allowing the split closure plates to direct the air away from occupants.

The internal closure plates of the Bi-Fold Vent clip onto a uniquely designed low prolife chassis which in turn clips within the aluminium profile, leaving only the height of the lids protruding above the profile. The chassis can be supplied in either white or black dependant on the colour of the patented closure plates.

The external section has a unique louvered design, to give the minimum amount of protrusion from the face of the profile. The louvred flyscreen sits beneath the reveal giving additional protection from the elements.

Moulded from high quality virgin ASA, Bi-Fold Vents are highly temperature and colour stable when compared to PVC-U. Initially available in white, black and anthracite grey in standard sets, bespoke and matching colours will also be manufactured.

For the heritage sector, we launched our Modular Vent which is perfect for fabricators manufacturing PVC-U vertical sliders or for smaller window or doors.

The Modular Vent is the best trickle vent in the market for watertightness (at 1000 Pa). The spring clip fitting (no screws) saves on installation time and the vent, though one of the shortest width trickle vents available, achieves a 2000 EQA performance for each module fitted. The Modular Vent is available in hundreds of colours and finish options and blends in perfectly with the window profile.

Since 2022, when building regulations changed, trickle vents have become a central product in the hardware category. The significant growth in the last three years of our Link Vent range is clear evidence that fabricators are ensuring they are manufacturing products that not only comply with regulations and but also meet, if not exceed homeowner expectations.

This year we have launched two more innovative trickle vents with the introduction of the Bi-Fold Vent and the Modular Vent, both of which are proving popular with our customers UK wide.

In 2026, we will continue listening to our customers and develop product solutions for the trickle vent, glazing accessories and hardware sectors.