Balancing carbon and performance

Chris Davis, from H.B. Fuller Kömmerling, discusses the balancing act between reduced operational carbon that comes with high performance, energy efficient IGUs, versus the increase in embodied carbon from additional glass, coatings and processing.

The construction sector is undergoing a seismic shift in how it understands and manages carbon. In just a few years, the industry has not only recognised the urgency of finite resource depletion but also begun the complex journey of balancing ever-increasing performance demands with the equally pressing need to design for recycling, repurposing, and disassembly.

Building design drivers are evolving rapidly – and as buildings are expected to last longer, so too must the components that form their fabric.

Few components illustrate this challenge more clearly than insulating glass units (IGUs). Discussions around their life-cycle performance highlight a delicate equation: the increase in embodied carbon (EC) that comes with adding glass layers, advanced coatings, and complex processing, versus the reduction in operational carbon (OC) achieved through improved thermal performance.

Getting this calculation right is essential. Understanding how much heating and cooling energy can be saved by a specific IGU configuration allows designers to offset that saving against the carbon cost of manufacturing, transporting, and installing it and to determine replacement strategies over time.

Measuring what matters

In theory, assessing an IGU’s carbon profile sounds straightforward. In practice, it requires detailed, assembly-specific data. While Environmental Product Declarations (EPDs) and Life Cycle Assessments (LCAs) exist for most individual components, finding accurate, consolidated figures for complete IGU assemblies is more challenging.

The IGU itself is then just one element within a larger window or curtain wall system – making precision even more important.

The hidden variable

One area of uncertainty is performance degradation over time. It is well understood that an IGU’s centre-pane U-value (Ug) does not remain constant. Argon gas loss and coating degradation, often triggered by edge seal failure, can have a direct impact. According to EN 672, argon loss in a standard 4/16/4 low-E unit (Ug = 1.0 W/m²K) can increase Ug by 0.2–0.3 W/m²K over time.

Historically, this might have been considered negligible. Today, even small changes in Ug values can critically influence the Uw values for the whole assembly – and therefore the building’s thermal performance. This is especially relevant as cavity gas not only boosts insulation but also protects high-performance low-E coatings from moisture-related degradation.

Research has shown the severe impact on emissivity if a cavity fails completely, but there is still more to learn about gradual performance decline. This is where dynamic carbon models will become invaluable – enabling designers to predict failure patterns, optimise maintenance cycles, and ensure IGUs continue to deliver on their OC savings in line with initial EC calculations.

In future, “effective service life” may prove more important than catastrophic failure points. An IGU may need replacement long before visible signs of failure appear, if its thermal performance has dropped below the level promised in the façade specification.

This shift in thinking means the industry can no longer hide from real-world performance tracking – especially as technologies already exist to measure gas concentration and emissivity in installed units.

To maximise the value of IGUs, the sector must not only achieve ultra-high insulation levels but also ensure durability that matches or exceeds competing materials.

This demands a reassessment of whether current single-cycle test protocols truly represent long-term performance. In practice, extended service life is achieved through a combination of high-quality materials and automated manufacturing for consistent, repeatable results.

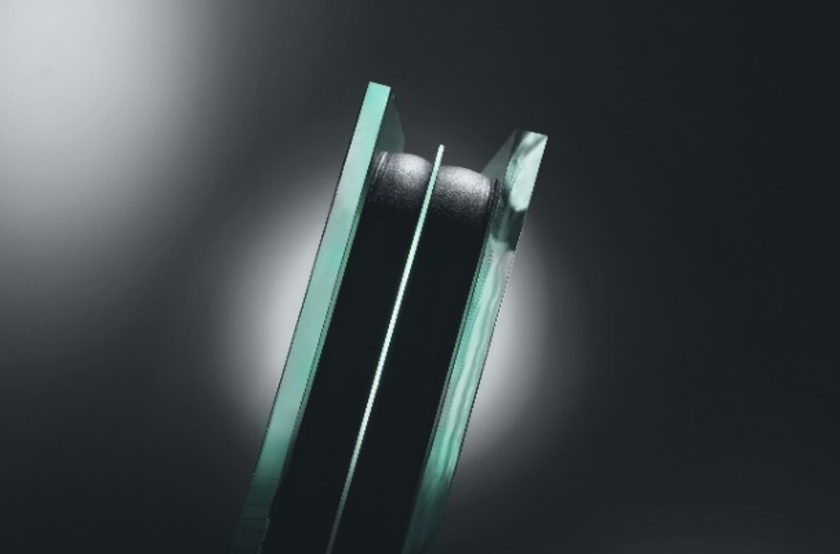

One example is the Ködispace 4SG reactive warm-edge thermoplastic spacer system from H.B. Fuller Kömmerling. This 21st-century spacer technology integrates spacer, desiccant, and primary sealant in a single component, reducing adhesive interfaces and dramatically lowering the risk of failure. Its reactive chemistry creates a near-indestructible bond to glass and secondary sealants, ensuring superior gas retention and moisture vapour resistance.

Paired with automated thermoplastic spacer (TPS) production, Ködispace 4SG delivers perfect spacer alignment for multi-pane IGUs, eliminates material waste, reduces labour requirements, and removes the need for conventional spacers, corner keys, and separate primary sealant application.

Looking ahead

Forthcoming changes to regulations such as Approved Document L (ADL) point toward more precise performance declarations – calculated for each frame size and layout rather than a single reference specification. Technologies like Ködispace 4SG are also enabling thin triple-glazed units, which will play a pivotal role in meeting tougher residential thermal performance requirements in the years ahead.

In short, carbon reduction and resource conservation are no longer optional targets – they are the benchmarks by which our industry will be judged. If IGUs can demonstrate a verifiable effective service life approaching 50 years, they will not only meet these benchmarks but set the standard for sustainable, high-performance building envelopes of the future.