Strength from adaptability

By Neil Parton, managing director of Elumatec.

One of the lessons of this year is that adaptability is essential: we have all experienced a sudden need to revise our plans.

We’ve learned to think differently and adopt new ways of working. We’ve seen priorities change as people and businesses have made the very best of a challenging situation.

While much of this has been forced upon us by the coronavirus pandemic, these actions are often productive, with or without a global crisis. One of our customers provides an outstanding example of this type of approach. They have optimised their potential by being adaptable and constantly looking for the next improvement.

The operation in question manufactures marquees and other temporary buildings. It will be no surprise that a significant amount of demand for their products comes from the events industry, which has been badly hit by this year’s restrictions. Rather than sitting back and waiting for better times, the business has found a market building and supplying Covid outdoor structures. These structures have the advantage of rapid deployment, providing emergency facilities or extra capacity for healthcare, leisure, commercial enterprises, and a whole host of industrial uses.

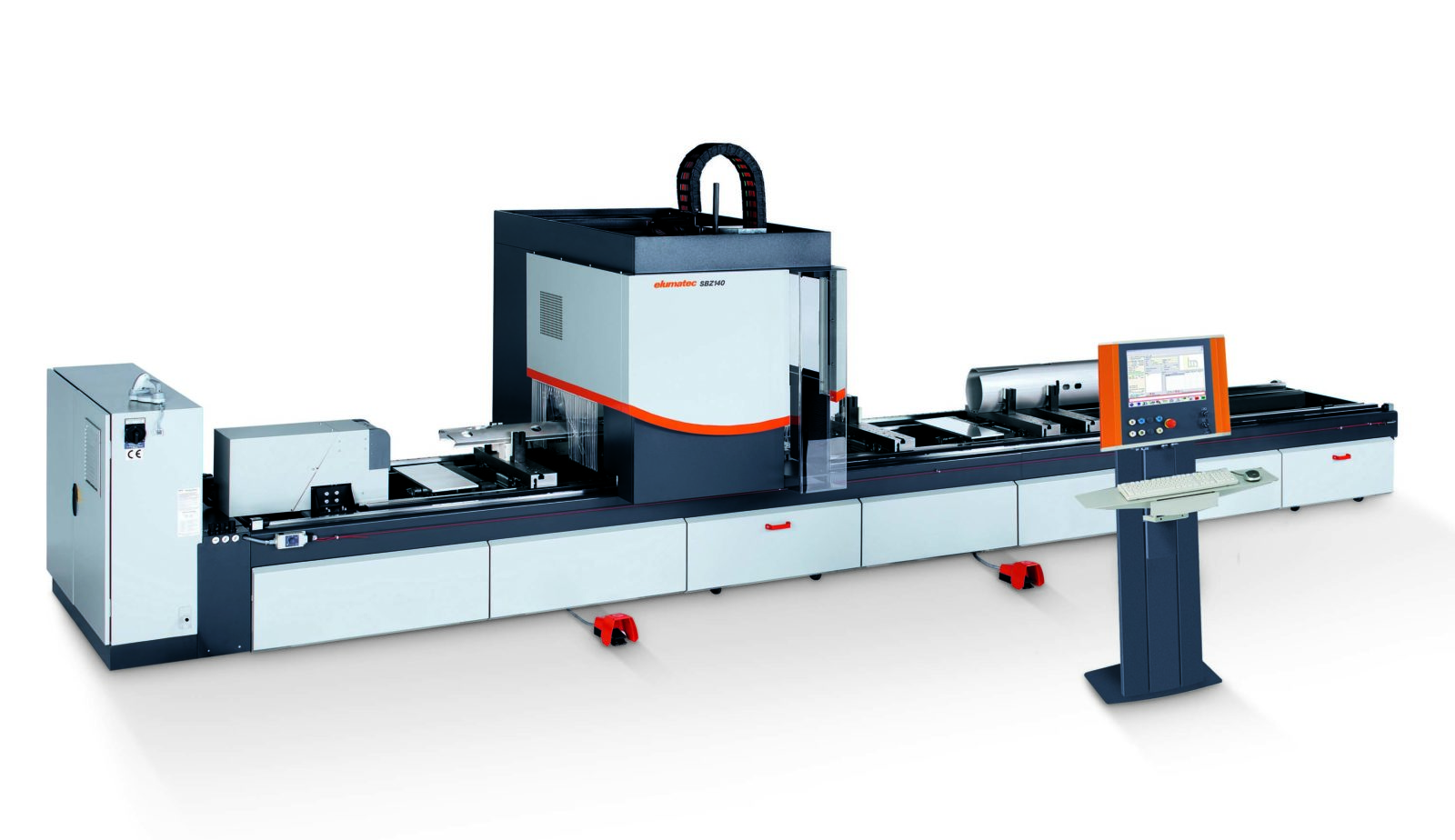

One of the company’s strengths is a highly skilled team but it takes more than good people to build a successful business. Investment in the right equipment is also crucial and we were happy when the business decided to invest in an Elumatec SBZ 140 machining centre for its UK manufacturing site. The machine is a great fit for the business because while it’s capable of volume output, it’s also very easy to set up. Ideal for an operation that produces both off-the-shelf and fully bespoke structures.

The SBZ 140 is a key product in the Elumatec portfolio. Just like the business in question, its adaptability has contributed to its success. The core four-axis precision machining centre is available with options to suit a wide range of applications, from aluminium and lightweight steel sections and from bulk to bespoke manufacturing. Different models suit different profile lengths and there are both air and water-cooled variants.

Across the entire range, there is an important common feature: these are machines designed for efficiency and economy. That means accuracy of machining operations and protection of the profiles being worked; it means that tool change times are minimal and rapid machining; and it means an easy to understand and familiar Windows operating system.

With the option of two separate working zones allowing machining in a shuttle operation, this is a reliable piece of kit that keeps idle time to an absolute minimum.

Of course, the machine itself is only half of the equation. It’s the software that completes the package, conferring even more of that vital efficiency. Around 12 months after it acquired the machine, the business realised it was not maximising its potential and upgraded from the standard eluCam software to our eluCad option.

Its reasons were simple. As a bespoke manufacturer, it was having to deal with plans and drawings supplied on files of various types; it was labour intensive to standardise what was supplied and convert the information into cutting lists, and this produced delays in their operation. Adding eluCad has removed that problem and its knock-on effects.

Because it is compatible with multiple file types − including .STEP files − eluCad makes it easy to produce a full breakdown of the required components from traditional plans or 3-D drawings.

“eluCad can be used from any location, and that’s been a real bonus for us,” The firm’s production manager said. “We’ve been able to program the machine remotely, and any amendments to plans have been incorporated without confusion or delay. That’s been essential as we’ve responded to many urgent requests during the pandemic.”

In this example, the manufacturer has shown the benefits of its adaptability. It already had an adaptable machine but was ready to embrace new software to get the very best out of it. As a result, when it needed to respond to rapidly changing demand, it has been able to do so.

Temporary hospital facilities, Covid-19 testing stations, extra space to allow workers to socially distance: it’s all possible when you are adaptable. You can change what you do, maintain the capacity for swift order turnaround, deliver high-quality products and maintain a reputation for excellence.